Methods: Wide subjects and new grounds

Mobile XRF analysis

X-ray fluorescence analysis (XRF) is a modern standard method in analytical chemistry. In recent years, this technique has been employed using handheld devices for field studies.

We use equipment from Thermo Scientific, including the Niton XL3t for rugged field conditions and the XL5 plus for more demanding analytical tasks. Since 2008, regular sulphur content mapping has been conducted to assess refined lignite in the seams.

One advantage of XRF is its ability to simultaneously measure a wide range of elements, from aluminium to lead, with concentrations spanning from a few ppm to percentages. Depending on the sample matrix, various calibration modes are available, enabling a broad range of applications.

Applications of mobile XRF analysis

- Analysis of alloys

- Trace element analysis in soils and silica dominated samples (10 – 1000 ppm)

- Analysis of ores and concentrates (0.05 – 100 mass%)

- Analysis of elements in light, carbon-based samples (plastics, wood, coal, lignite)

- Possibility of personal calibration modes for any elements

In applied field analysis, this method complements wet chemical analysis by allowing an almost unlimited number of measurement points, providing high representativeness.

Additionally, the equipment can be used in the laboratory, where sample pre-treatment (drying, fine grinding) and longer measurement times enhance the accuracy of the method. Accuracy is validated through the measurement of certified standards.

The wide element spectrum and the combination of fast analysis and field methods continually open up new applications, from laboratory analyses to element screening on rock faces, trenches, or drill cores.

If you have any analytical questions, feel free to reach out.

To Geology »

Microlithotype analysis (QMAT)

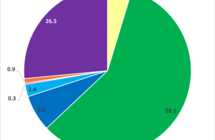

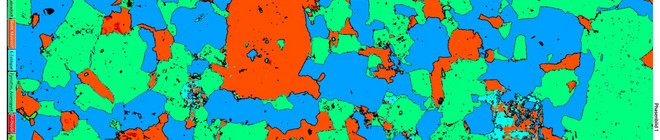

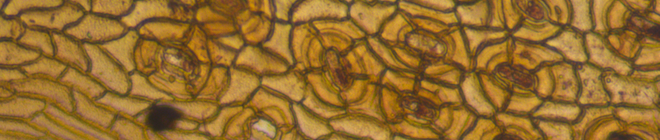

Quantitative microlithotype analysis (QMA) of soft lignite after the method of SONTAG/TZSCHOPPE/CHRISTPOPH (1965) was performed routinely since 1968 and upgraded in the year 1980 by SCHNEIDER to QMAT (quantitative microlithotype analysis with evaluation of textite).

Mechanical properties of lignite can be explained by microscopic recognizable structural features. Hence the suitability of various lignites for mechanical refining, like milling and agglomeration, is determinable by microscopic evaluation of structural features. The mechanical efficient microscopic structural area is defined as the microlithotype.

To Microscopy »

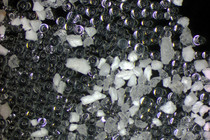

Particle analysis

At particle analysis we deal with the spatial and material description of solids with a size of a few mm up to nanometer size. The range of tasks reaches from natural and artificial fibers to deposits in fluidly affected plants to analysis of dust in surroundings or at the workplace.

The advantage of particle analysis at LAOP is the combination of light optical, electron optical and microchemical methods, which make a profound sample description possible. Alternatively, the appropriated method for your problem can be chosen specifically from our analytical range.

Applications of Particle Analysis

- Morphological and microchemical characterization of dusts at industrial as well as settlement areas

- Analysis of deposition in pipelines

- Investigation of fibers from filter systems

- Description of tribological particles in hydrocarbon containing fluids (engines, generators, hydraulics)

- Analysis of fine sediments in natural and artificial waters

A particle analysis at LAOP can be realized qualitatively as well as quantitatively. Parameters in focus are: size, shape, surface and chemical composition.

To Microscopy »

Solid rock analysis

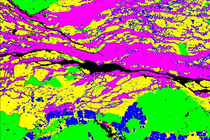

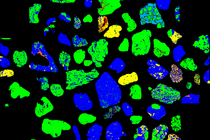

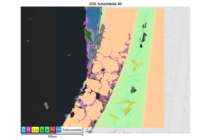

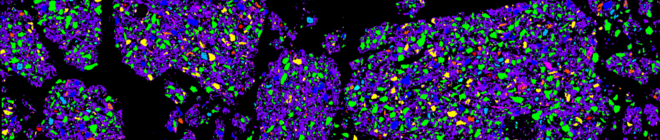

The mineralogical composition of rock samples is crucial for numerous applications in engineering sciences. These applications range from estimating pore space in geothermal studies to predicting wear in tunnel construction. Pore space data can be determined through image analysis of composite, density-dependent grayscale images (BSE contrast). Additionally, the type and content of cement in sedimentary rocks are characterized and quantified.

Mineralogical phase distribution can be used to make wear predictions. By applying the Cerchar Abrasivity Index (CAI) to the individual phases, the equivalent quartz content of the sample can be inferred. For texture-related questions, color-coded images of the CAI are generated.

LAOP, through SEM/EDS analysis of sample surfaces spanning several square centimeters, provides results that are similarly representative to those obtained by traditional thin-section microscopy. In addition to the mineralogical phase distribution, the chemical distribution at the micrometer scale is also captured. Unlike MLA or QEMSCAN, the phase data are not abstracted but are calculated from each individual pixel of the microchemical image.

To Microscopy »

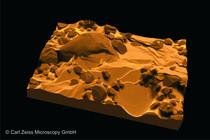

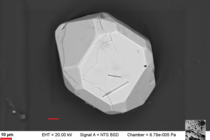

SEM

ScanningElectronMicroscopy is a profound method for the illustration and analysis of micro structures since more than 30 years. It supplies data about surface geometry, mineral content or crystallography of the sample material in a much higher resolution spectrum as light microscopy. Further a higher level of automation of analysis can be reached which leads to significant increase of accuracy and saving of time.

The technical progress and an economic production of micro electronic devices do not confine electron microscopy to university or research institution anymore. Today such equipment can be found in laboratories of industry, medicine and material science.

At LAOP investigation of palynology, heavy mineral analysis, paleobotany and micro chemistry are supported by the Zeiss EVO MA 10 with Oxford X-max 50 EDS.

Applications of ScanningElectronMicroscopy

- Illustration and comparison of recent and fossil spores and pollen, for example as basis of stratigraphic classification

- Micro chemical classification of the composition of heavy minerals as an aid for provenance analysis or for the prospection of placer deposits

- Analysis of slag, cinder and coverings of surfaces resulted from power plant processes

- Analysis of type, origin and micro chemistry of diverse dusts, for example caught particles from particle air drift experiments or fine particulate matter in inhabited areas

- Analysis and comparison of fossil and recent woods by means of wood-anatomic characteristics

- Image of all micro structures of geological, archeological and environmentally relevant samples

The installed SEM at LAOP works with a LaB6-cathode and reaches resolutions of 2 nm at 30 kV. It disposes a mode of operation with variable pressure for poorly conducting or degassing samples. For improvement of the samples conductivity and therefore for the taking of high-resolution images, coating techniques from Cressington are applied. Those are designed as dual-kit and enable a carbon coating as well as a coating with gold or platinum. Apart from the electron microscopic images, geometric measurements right up to volumetric analysis can be done. A real 3D surface picture can be achieved by means of the 5-segment-HD backscatter detector.

The EDS-detector enables point and line analysis as well as element mapping. This widens one’s understanding of the present sample material by the micro chemical composition and therefore complements our methods of light microscopy. Classification and presentation of individual phases as well as an automated particle analysis are optional features.

To Microscopy »

Heavy mineral analysis

Depending on the research question and the desired results, we utilize various methods for heavy mineral analysis. These include the classic approach using polarization microscopy, and semi-automated analysis with SEM/EDS, or a combination of both, which can often be beneficial.

The process begins with the chemical treatment and sieving of sediments, with sedimentary rocks crushed beforehand. In the sieved grain size fractions, light minerals are separated from heavy minerals, the latter being defined by a density of >2.9 g/cm³. Separation is achieved using a separation funnel and the heavy liquid sodium polytungstate, which offers significant advantages over other heavy liquids, being non-toxic, non-flammable, easy to handle, and reusable.

From the separated heavy mineral fraction, grain mounts are prepared for light microscopy analysis. We use Meltmount (refractive index n=1.662) as the mounting medium. Minerals are then counted and identified under a polarization microscope based on optical properties such as color, cleavage, pleochroism, extinction, refractive index, birefringence, and conoscopic figures. Transparent and opaque minerals are distinguished, with only the transparent ones determined via transmitted light microscopy. Opaque minerals are counted as a separate group and further classified using SEM/EDS. Additionally, light microscopy allows for documenting the weathering and dissolution of mineral surfaces. A minimum of 300 transparent grains is recommended for a thorough analysis.

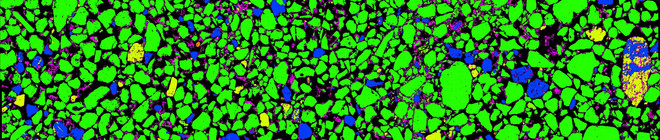

For SEM/EDS analysis, the grain fractions are embedded in epoxy resin and polished. The grains are then classified into their corresponding mineral groups based on their chemical composition. This method's advantages include the identification of opaque minerals and the ability to examine a significantly larger number of grains. Moreover, SEM/EDS allows for various geochemical analyses, such as differentiating garnet varieties or detecting trace elements within grains.

Applications of Heavy Mineral Analysis

- Petrographic characterization of sediments

- Stratigraphic interpretation by analyzing mineral changes in drill cores or profiles

- Investigating the paleogeographical evolution of sedimentary basins, providing insights into provenance, transport routes, tectonic influences, diagenesis, and climate conditions

- Quantifying rare earth element content, which often accumulates in heavy mineral placers

For the last application, in addition to SEM/EDS, our mobile XRF device can determine elements like yttrium, lanthanum, cerium, neodymium, and praseodymium, ranging from percentages to mid-ppm levels. This aids in exploring Yttrium and Cerium-rich deposits in drill cores and geological profiles.

To Microscopy »

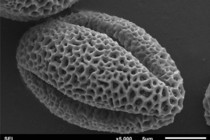

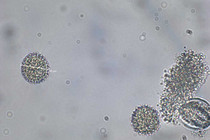

Pollen analysis

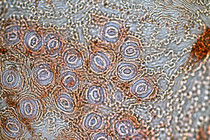

Pollen analysis (palynology) is a method that qualitatively and quantitatively examines both recent and fossil pollen grains and spores. The analysis of pollen grains and spores of the Lusatian Miocene lignite seams is applied as an additional method to cuticular analysis.

The focus here is on the determination of the facies and stratigraphic classification of seams, seam banks and accompanying horizons.

In order to obtain a more comprehensive picture of pollen and spores in the Tertiary and to preserve a methodology that has been used for many decades, an introduction to the early Tertiary pollen stratigraphy takes place. The biostratigraphic evaluation is carried out using the stratigraphically usable spore and pollen forms published by W. Krutzsch for the Central European Early Tertiary.

The preparation of the samples is realized in our laboratory in Lauta. We are specialized in lignite and coal-bearing samples. The preparation takes place by the use of various chemicals to macerate organic components. Mineral particles are separated using gravity separation with sodium polytungstate. After the preparation process, long-term preparations (glycerin gelatin) are produced. The microscopic evaluation is carried out at 400x and 600x magnification. Approximately 300 pollen grains and spores are counted per sample. After the qualitative and quantitative analysis of the pollen content, a pollen diagram is created from the data obtained.

Applications of Pollen Analysis

- Facies identification of Tertiary lignite

- Biostratigraphy: stratigraphic classification of lignite seams, layers and accompanying horizons

- Answering specific questions, such as assigning a sample to the Tertiary or Quaternary period

- Representation and examination of fine structures using the scanning electron microscope

Sediment petrography

In addition to heavy mineral analysis, various investigations are offered for light minerals as well. These can be more precisely characterized through thin-section analysis, with a primary focus on different quartz formations and feldspar varieties. At the SEM/EDS, minerals undergo surface analysis, where grain shape, rounding, crack formation, dissolution phenomena, and grain aggregation are documented. Additionally, geochemical properties can be determined using SEM/EDS.

A mobile XRF device is used for point measurements, sample analysis, or generating measurement series on drill cores. For instance, in the latter case, an elemental screening can be conducted to geochemically characterize sedimentary sequences.

For samples ranging from coarse sand to gravel, stereomicroscopy is used for description, determining composition, degree of roundness, surface texture, and color. Furthermore, a count of gravel composition, in accordance with the small bedload analysis TGL 25232, is also possible.

Regardless of grain size, each sample can be subjected to particle analysis or phase analysis with digital image evaluation.

Applications of Sediment Petrography

- Petrographic characterization of sediments

- Making stratigraphic statements, which can be indicated by the mineral change within a drill core or geological profile

- Investigation of the palaeogeographical development of sedimentary areas, including conclusions about the delivery area, transport, tectonics, diagenesis and climate

- Microchemical classification of heavy mineral compositions as an aid to provenance analysis or for the prospection of placer deposits

- Determination of grain size-independent enrichments or depletions of e.g. heavy minerals such as zircon

- Determination of the content of rare earth elements, which can preferably accumulate in heavy mineral placer

pore space analysis

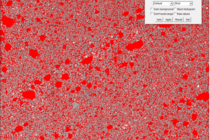

The pore space analysis of loose sediments, without strong diagenetic overprint or cementation, is challenging. In this process, the sampling and preparation of the undisturbed samples are crucial for accurately representing the original sedimentary textures.

The dried, undisturbed samples are embedded with different resins under variable pressure conditions, depending on the sediment composition. The hardened samples are then cut and processed into polished sections.

Using SEM/EDS, several square centimeters are analyzed by density contrast (BSE). These high-resolution BSE images can then be analyzed using image processing software, resulting in pore space quantification. Additionally, large-format areas are analyzed microchemically and phase-analytically. The analyses provide information on:

- sedimentological character (facies, provenance, transport processes)

- soil mechanics issues (pore size distribution, packing density)

- fluid mechanics behavior (effects of erosion and suffusion)

To Microscopy »

Metallography

Metallographic analytics at LAOP are oriented towards electron microscopy, but reflected-light methods can also be applied. Typically, we work with tailored samples or polished sections. The treatment of the sections is carried out using cutting and polishing equipment from the company Buehler. The microscopy equipment comes from Leica and Zeiss. Microchemical analyses are done by an EDS-detector from Oxford Instruments.

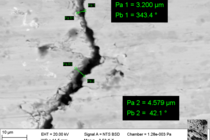

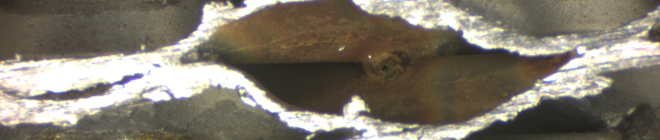

One application is the analysis of wear and failure areas of components and workpieces. Thereby grain texture and fractures or cracks can be observed down to the upper nanometre range. SE imaging makes even the smallest topographical unevenness visible.

In terms of corrosion analysis, the electron-optical phase analysis is the method of choice. Microchemical examinations of the original and corroded workpiece parts can be used to conclude the corrosion reason and degree of the usually very complex corrosion processes in components. The analyses using EDX also provide the chemical composition of the metallic phases and the corrosion products.

To Microscopy »

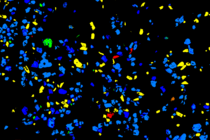

Mineral Phase Analysis

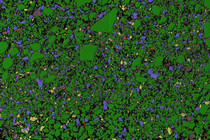

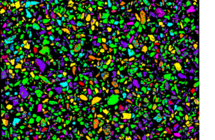

In mineral phase analysis, the phases present in the sample are identified using SEM/EDS. Sediments and soils are initially processed and sieved into subfractions, followed by embedding in epoxy resin. The samples are then ground and polished.

Analysis of the polished samples is conducted in a Scanning Electron Microscope using EDS, where large-format, high-resolution elemental distribution maps are generated. In the next step, phases of uniform chemical composition are calculated from the distribution data and analyzed using image processing techniques. The results from the individual subfractions are then combined to calculate a weighted mean for the entire sample. Any gravel fractions present in the sample are examined and identified under a stereomicroscope, allowing the phase components to be estimated and incorporated into the final results.

Applications of Mineral Phase Analysis

- Verification of purity in certified quartz sands

- Determination of grain size-independent mineral enrichments or depletions

- Drawing conclusions about the source material of sediments

To Microscopy »

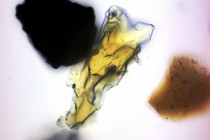

Cuticular analysis

Cuticular analysis is used to determine facies in coal and coal-bearing / organic clastic sediments. It uses in lignite enclosed leaf fragments, whose cuticles are present in fragments (Cuticulae dispersae) in the preparation. The classification of facies enables:

- The determination of fine stratigraphy of the seams

- Statements about the stratigraphic correlation of seams, layers and accompanying horizons

- The proof of representation of the macropetrographic identification of lignite

This working method, further developed by Dr. W. Schneider, has been used at LAOP for many years on the Miocene lignites of the Lusatian mining district and is partly adapted to other lignite districts. Project references are available from both the Lower Rhine district and the Central German mining area.

A cuticular analysis at LAOP can be realized qualitatively as well as quantitatively. A detailed description and application of this method can be found here:

To Microscopy »